652E MOWER

QuikTrak™ Stand-On Mower

- Compact design for easy hauling

- Hydrostatic drive system

- Commercial-quality engine

- Easy to maintain

Apply For Financing

View Product Brochure

Features

Overhead view of 652E showing compact design

Overhead view of 652E showing compact design Side view of 652E showing compact design

Side view of 652E showing compact designFrom the operator's platform to the mower deck, John Deere QuikTrak™ Mowers have a compact and functional design:

- The compact design allows the QuikTrak to operate in tighter areas that a larger machine cannot. Often, this means the area can be mowed with a QuikTrak so it is not necessary to switch to a walk-behind mower, reducing the time on site.

- With the compact design of QuikTrak Mowers, less space is required on a truck or trailer - which can mean there is room for an extra mower, resulting in less time on property, saving time and money.

Mowing a tight area with 652R QuikTrak

Mowing a tight area with 652R QuikTrak 652R QuikTrak

652R QuikTrakWhether mowing hills or on level terrain, trimming or mowing straight-away, the operator of a John Deere QuikTrak is able to affect the performance of the machine with their body:

- The compact design of the QuikTrak allows the operator to use their body to help control the machine.

- The innovative QuikTrak design puts the operator in line with the rear axle to keep traction when mowing across slopes, providing greater control.

- Faster ground speeds get work done quicker.

- Better traction on slopes gives more control and increased productivity.

- Superior stability gives more control and confidence when mowing hillsides.

- Better visibility allows more-timely operator reaction to the terrain and obstructions.

- Standing area is designed for improved range of motion to allow the operator more room to move and avoid obstacles.

- Minimal operator-station obstruction allows safe and fast exits for clearing mower-path obstacles.

- Operator area is designed for more comfort and less fatigue.

Inset caster wheels (652E shown)

Inset caster wheels (652E shown) Inset caster wheels (652R shown)

Inset caster wheels (652R shown)John Deere QuikTrak Mowers are designed, tested, and manufactured to provide the best commercial mowing machines available:

- Bull-nosed shape of the front edge of the mower deck allows caster wheels to be set back further, closer to the blades, for more effective ground following capability.

- Compact design takes less space for mowing tighter areas and may allow room for an extra machine when hauling to the worksite.

652E QuikTrak™ Mower

652E QuikTrak™ Mower 652E QuikTrak mower deck

652E QuikTrak mower deckA well-designed mower deck can make the difference between just getting the job done and getting eye-catching results. The 7-gauge, 0.179-in. (4.6-mm) fabricated mower deck delivers a high-quality cut in more diverse conditions to enhance mowing performance.

Key features of the fabricated mower deck include:

- The mower deck is manufactured from 7-gauge, 0.179-in. (4.6-mm) steel.

- A compact footprint delivers greater maneuverability when working in tight quarters.

- A deep-deck design delivers excellent airflow so material is processed quickly and efficiently.

- A powerful vacuum effect is created by the deck's unique air-flow design, which pulls more grass upright so that the blades can cut more evenly.

- 48-in. to 61-in. (122-cm to 155-cm) decks come standard with an adjustable striping flap to enhance the after-cut appearance.

Flexible mower-discharge deflector

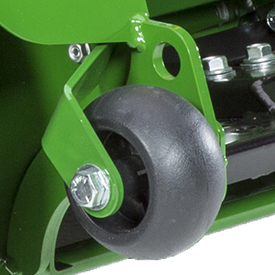

Flexible mower-discharge deflector Large, inset caster wheels

Large, inset caster wheelsThe wide-discharge opening and raised deflector provide even clipping dispersal for an excellent finished appearance in all conditions.

Caster wheels and anti-scalp rollers contribute to a smooth, even cutting job:

- Large, flat-free caster wheels carry the mower deck smoothly over the lawn.

- Caster wheels are recessed to reduce the vehicle footprint and turning radius.

- With the wheels less exposed, there is less chance they will get snagged by immovable obstacles, thus improving maneuverability and reducing damage.

- Anti-scalp rollers are double-captured for durability. They enable the deck to float over the ground and provide a smooth, level cut on even the most challenging terrain.

Easy cutting-height adjustment

Easy cutting-height adjustment Easy-to-remove mower deck shields

Easy-to-remove mower deck shieldsA combination of shims and spacers can be used to set cutting height and level precisely:

- Gap in spacers allows them to be moved by just lowering the caster wheel; no need to remove it.

- Larger changes to cutting height can be made by changing the location of the support arm where it bolts to the mower deck.

Mower deck shields are easy to remove, with one knob, for access to the drive belt and other service points.

Optional mulching attachment

Optional mulching attachment and blades (similar design shown)

Optional mulching attachment and blades (similar design shown)

Optional mulching attachment and special mulching blades are available:

- This is a high-performance mulching attachment that includes formed steel baffles to control the material for superior performance.

- The special mulching blades can also be used for side discharging, though overall cutting performance may be slightly less than with the standard blades.

Engine

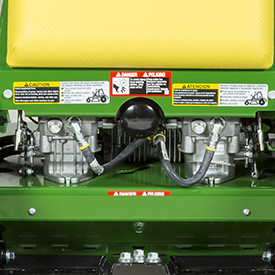

Engine Heavy-duty dual stage air cleaner

Heavy-duty dual stage air cleanerA commercial-quality, 22-hp (16.4-kW) at 3600 rpm, air-cooled engine powers the QuikTrak™ Mower:

- Overhead valve design

- More horsepower and torque per cubic inch of displacement

- Better fuel efficiency

- Full-pressure lubrication with full-flow filter

- Reduces engine wear by ensuring proper lubrication, even when operating on hillsides or uneven terrain

- Filtered oil reduces risk of contamination for increased engine life

- V-twin design

- Fast starts

- Smooth operation

- Vertical shaft for efficient transfer of power to the transmission and mower

- Standard dual-element, canister-type, dry replaceable, heavy-duty air cleaner with secondary safety element

- Fuel pump for consistent and reliable fuel supply to the carburetor

- 50-state compliant engine, which complies with strict U.S. Environmental Protection Agency and California Air Resources Board emission standards without loss of horsepower or torque

- Air-cooled engine design for minimum maintenance and maximum reliability

- Standard cleanout ports for easy access to remove debris collecting in cooling fins

- Aluminum cylinder block

- Effectively dissipates heat

- Lightweight and strong construction

- Extends engine life due to elimination of debilitating engine temperatures

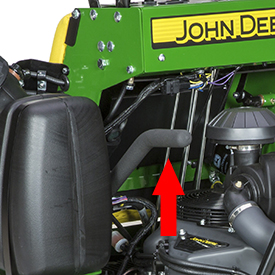

Engine oil-fill tube, filter, and drain

Engine oil-fill tube, filter, and drain

The engine is equipped with a replaceable oil filter for longer engine life.

Engine oil fill/check tube, oil filter, and oil drain are located close together for easy and convenient service.

Propane conversion kit on a Walk-Behind Mower

Propane conversion kit on a Walk-Behind Mower Propane conversion kit on a ZTrak Mower

Propane conversion kit on a ZTrak MowerJohn Deere provides application-specific Environmental Protection Agency (EPA) and California Air Resources Board (CARB) approved field-installed propane conversion kits for specific John Deere Commercial Walk-Behind Mowers, QuikTrak Mowers, and ZTrak Mowers. The conversion kits include all components required to convert the engines to operate on propane fuel. Single-tank or dual-tank brackets (depending on the vehicle) are provided for securely holding the propane tank(s) to the vehicle.

Propane tanks are not included.

An optional altitude kit is required when operating at altitudes above 2000 ft (610 m). The operator’s manual with the propane conversion kit provides further details. Parts must be ordered separately through John Deere Parts.

Propane facts:

- Propane is flammable and commonly used as a fuel.

- The molecular formula of propane is C3H8, and it is in the family of liquefied petroleum gases (LP gases). The other LP gases include butane, propylene, butadiene, butylene, isobutylene, and mixtures thereof.

- Propane is commonly available and has proven to be a dependable, safe, economical, and clean-burning fuel. It can be used as household fuel, industrial fuel, and fuel for internal combustion engines. Propane has been used as a fuel since 1910.

- At atmospheric pressure, propane boils at -44°F (-42.2°C), meaning it typically exists as a vapor. However, when contained under pressure, such as in a propane cylinder, it can exist as a liquid.

- Propane is naturally odorless, but includes an additive odorant, usually mercaptan, which gives it a distinct odor.

- Vapor propane is heavier than air, meaning it will settle in low areas such as along the ground or in drains.

Advantages of John Deere propane conversion kits include:

- Reduced fuel costs, up to 30 percent depending on fuel prices

- Lower emissions

- Reduced fuel-system maintenance

- Maintains John Deere warranty

- EPA and CARB certified

- May qualify for national and state rebate and incentive programs. Please visit www.propane.com/commercial-landscape/programs-and-incentives/ for further information.

Propane tank mounting bracket options:

Single propane tank shown on QuikTrak Mower

Single propane tank shown on QuikTrak Mower Dual propane tanks shown on ZTrak Mower

Dual propane tanks shown on ZTrak MowerOptional tank configurations and sizes are available to provide operators the ability to tailor for run time:

- Commercial Walk-Behind Mowers have only a single-tank mounting option.

- The single-tank bracket is designed for one 20-lb (9.1-kg) or 33-lb (15-kg) Worthington tank.

- Tank is not included.

- The single-tank bracket is designed for one 20-lb (9.1-kg) or 33-lb (15-kg) Worthington tank.

- QuikTrak Mowers have single-tank and dual-tank mounting options.

- The single-tank, right-side bracket is designed for one 33-lb (15-kg) Worthington tank.

- Tank is not included.

- The dual-tank brackets are designed for two 20-lb (9.1-kg) Worthington tanks.

- Tanks are not included.

- The single-tank, right-side bracket is designed for one 33-lb (15-kg) Worthington tank.

- ZTrak Mowers have single-tank and dual-tank mounting options.

- The single-tank, left-side bracket is designed for one 33-lb (15-kg) or 43-lb (19.5-kg) Worthington tank.

- Tank is not included.

- The dual-tank brackets are designed for two 33-lb (15-kg) Worthington tanks.

- Tanks are not included.

- ZTrak Mowers with dual-tank configurations are not compatible with any material collection systems.

NOTE: Reference the Propane and Attachment Compatibility Chart to determine tank configurations that are compatible.

Estimated run-time comparison

| Engine displacement | FS603cc | FS726cc | FX726cc | FX852cc |

| Average consumption (lb [kg]/hr) | 3.9 (1.8) | 4.2 (1.9) | 4.2 (1.9) | 5.8 (2.6) |

| Run time (hours) with 20-lb (9.1-kg) tank | 5.1 | 4.8 | 4.8 | 3.4 |

| Run time (hours) with 33.5-lb (15.2-kg) tank | Not available | 8.0 | 8.0 | 5.8 |

| Run time (hours) with 43.5-lb (19.7-kg) tank | Not available | 10.4 | 10.4 | 7.5 |

Field-installed propane conversion kit compatibility:

NOTE: Conversion to propane is not intended for units with engines having more than 250 hours of use.

Commercial Walk-Behind Mowers (model year 2018 and prior)

| WG Series | WH Series | WHP Series | |||||||||

| Model | WG32A | WG36A | WG48A | WH36A | WH48A | WH52A | WH61A | WHP36A | WHP48A | WHP52A | WHP61A |

| Engine model | FS481V | FS481V | FS481V | FS481V | FS600V | FS600V | FS691V | FS481V | FS600V | FS600V | FS691V |

| Engine displacement | 603 cc | 603 cc | 603 cc | 603 cc | 603 cc | 603 cc | 726 cc | 603 cc | 603 cc | 603 cc | 726 cc |

| Propane kit model number | Not available | Not available | Not available | FS603cc | FS603cc | FS603cc | FS726cc | FS603cc | FS603cc | FS603cc | FS726cc |

QuikTrak Mowers

| E Series | M Series | R Series | |||||||

| Model | 652E | 636M | 648M | 652M | 648R | 652R | 652R EFI | 661R | 661R EFI |

| Engine model | FX691V | FS600V | FX691V | FX691V | FX691V | FX730V | ECV740 EFI | FX730V | ECV740 EFI |

| Engine displacement | 726 cc | 603 cc | 726 cc | 726 cc | 726 cc | 726 cc | 747 cc | 726 cc | 747 cc |

| Propane kit model number | FX726cc | Not available | Not available | Not available | FX726cc | FX726cc | Not available | FX726cc | Not available |

Commercial ZTrak Mowers

| E Series | M Series | R Series | |||||||||

| Model | Z915E | Z920M | Z925M EFI | Z930M | Z945M EFI | Z950M | Z955M EFI | Z960M | Z930R | Z950R | Z970R |

| Engine model | CV742 | FX730V | ECV740 | FX801V | ECV850 EFI | FX850V | ECV860J EFI | FX921V | FX801V | FX850V | FX1000V |

| Engine displacement | 747 cc | 726 cc | 747 cc | 852 cc | 824 cc | 852 cc | 824 cc | 999 cc | 852 cc | 852 cc | 999 cc |

| Propane kit model number | Not available | FX726cc* | Not available | FX852cc* | Not available | FX852cc* | Not available | Not available | FX852cc* | FX852cc* | Not available |

Worthington tanks are manufactured by Worthington Industries, Inc.

652E QuikTrak™ Mower

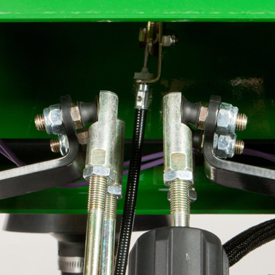

652E QuikTrak™ Mower Hydrostatic pumps

Hydrostatic pumpsQuikTrak Mowers use a heavy-duty hydrostatic pump and wheel-motor drive system that gives reliable and consistent performance and long life:

- Heavy-duty components stand up to the stress of commercial use.

- Individual pump and wheel motor design allows placement of these heavy components low in the vehicle for a low center of gravity and excellent hillside stability.

Two Hydro-Gear™, 0.73-cu in. (12-cc) axial piston, variable-displacement pumps provide hydraulic power to the wheel motors:

- Pumps are linked to the hand-control levers to allow the operator to make speed and directional changes.

- Rugged construction is ideal for high-performance commercial use.

- Piston design gives efficient and consistent performance.

- A replaceable hydraulic filter helps ensure long life of the pumps and wheel motors.

Two individual, 15-cu in. (245.8-cc), piston wheel motors power the QuikTrak drive wheels. Their heavy-duty construction and super-efficient axial-piston design provides superior performance and seamless power to the wheels:

- Integrated high-pressure shaft seal gives greater reliability.

- Large bearings are designed with the capacity to carry heavier loads and give long life.

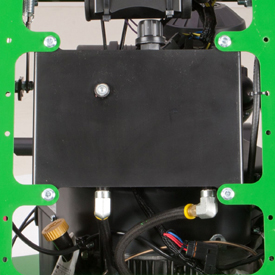

Transmission oil filter

Transmission oil filter Transmission fluid oil reservoir

Transmission fluid oil reservoirA spin-on type replaceable hydraulic oil filter is conveniently located:

- Extends life of transmission components by keeping oil clean

- Easy-to-reach for easy and fast service

A hydraulic fluid oil reservoir is located behind the leaning pad:

- Located in a cleaner environment

- Easy to access for inspection and service

- Sight glass built into the tank reduces risk of contamination when checking fluid level

Transmission bypass valve

Transmission bypass valveTransmission bypass valves are provided on each hydrostatic pump to permit moving the QuikTrak without the engine running.

Hydro-Gear is a trademark of Hydro-Gear Limited Partnership AF Holding Company.

QuikTrak™ Mower mowing (652R shown)

QuikTrak™ Mower mowing (652R shown) Control console (652E shown)

Control console (652E shown)Controls are color coded and logically placed to make them easy for the operator to find and use:

- Ground speed and direction are easily controlled by moving the two hand-lever hydrostatic drive controls forward or reverse.

- Speeds are infinitely variable up to 9.5 mph (15.3 km/h) forward and 5.5 mph (8.9 km/h) reverse.

- A positive neutral-lock position for the levers provides added safety.

- Two stationary reference bars are provided for operator convenience and security.

- Front reference bar is included to control speed and reduce fatigue from control lever operation.

- Rear reference bar is included to make reverse operation easy while maintaining operator confidence.

- Control levers return to neutral automatically for safety and convenience.

Separate choke is easy to locate and use.

- Less adjustment is needed with the separate choke.

Brake lever (engaged position)

Brake lever (engaged position) Brake bar

Brake barA tire brake is provided to give stability for parking the vehicle on hillsides and for transport; it should be engaged whenever the machine is not being used:

- Brake must be engaged to start the machine, for added safety.

- The tire brake is easily adjusted, if necessary, to maintain effective operation.

Mower deck height-of-cut adjustment (648R, 652R, 661R)

Mower deck lift handle (648R, 652R, 661R)

Mower deck lift handle (648R, 652R, 661R) Mower deck height-of-cut adjustment (648R, 652R, 661R)

Mower deck height-of-cut adjustment (648R, 652R, 661R)On the 648R, 652R, 652R EFI, 661R, and 661R EFI QuikTrak Mowers, an easy-to-use cutting height adjustment system allows the operator to adjust the mower deck cutting height with no tools and minimal effort:

- Pull the lift lever back to the fully-raised position.

- Remove the tethered pin and place it at the desired cutting height.

- Lower the lift lever; the lift lever and mower will stop at the desired cutting height.

NOTE: Additional information on mower cutting height adjustment can be found in the mower deck section.

652R QuikTrak™ Mower

652R QuikTrak™ Mower Mower discharge deflector

Mower discharge deflector Curb wheels

Curb wheels

Key safety features of QuikTrak Mowers include:

- Start circuit requirements

- Park brake engaged

- Power take-off (PTO) disengaged

- Control levers in neutral

- Ignition key used to start the engine

- A high-quality polyethylene mower-discharge deflector

- Deflects if it strikes a solid obstruction, causing less damage

- Returns to its original shape and function

- Operator station designed to allow fast exit

- Two large curb wheels

- Easy to remove and replace shields

- Stationary handles on either side of the traction controls for operator security

- Control levers return to neutral when released

Mower deck safety certification

QuikTrak mower decks are evaluated by the manufacturer (John Deere Turf Care) and conform to American National Standards Institute (ANSI) B71.4 2004 safety certification specifications for commercial turf care equipment.

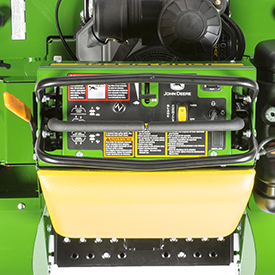

652E QuikTrak™ Mower

652E QuikTrak™ Mower Open engine compartment

Open engine compartmentAll service components are easy to access:

- Servicing is simplified because of the open engine compartment.

- All service and maintenance points are within easy reach.

Heavy-duty canister-type air cleaner

Heavy-duty canister-type air cleaner Engine oil fill/check tube and oil filter

Engine oil fill/check tube and oil filterCanister-type heavy-duty air cleaner is easy to reach and easy to service:

- Air cleaner has two filter elements; a large outer filter and a smaller inner safety filter.

- Both filters are easy to access and easy to change.

Engine oil service points are grouped together in easy-to-reach locations:

- Reduces the time required to check and/or change the oil and filter.

Leaning pad raised for service access

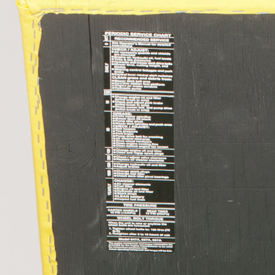

Leaning pad raised for service access Periodic service chart

Periodic service chartSimply raising the leaning pad exposes the hydrostatic oil reservoir, control linkage and other service areas.

A periodic service chart is provided for convenience in keeping up on required service.

Easy-to-remove access panel

Easy-to-remove access panel Hydrostatic transmission control linkage

Hydrostatic transmission control linkageRemove service access shields on the mower deck, battery box, etc. to service the machine:

- Panels are easy to remove and install

Threaded ball and socket rod ends are used throughout the QuikTrak Mowers:

- Provide precise control over a long period of time

- Easily replaced when necessary

Hydrostatic pump maintenance access

Hydrostatic pump maintenance access Transmission bypass valve

Transmission bypass valveAccess to check and service the hydrostatic pumps and motors is readily available at the rear of the machine.

Transmission bypass valves are located on the hydrostatic pumps to enable moving the vehicle without the engine running.

Battery box

Battery box Battery cover removed for service access

Battery cover removed for service accessA secure battery box is provided to protect the battery, for reliable operation:

- Cover is easily removed for servicing the battery.

Front tie down

Front tie down Rear tie down

Rear tie downFour tie-down locations, two at the front and two at the rear, are provided for safely towing or anchoring the vehicle.

Specifications

| Key Specs | 652e-mower Current Model |

|---|---|

| Engine Manufacturer/model | FX691V |

| Engine Power | Gross at 3,600 rpm: 22 hp 16.4 kW |

| Fuel tank capacity | 5.6 U.S. gal. 21.2 L |

| Mower deck Size | 52 in. 132 cm |

| Blade tip speed | 18,900 fpm 5,761 m/min |

| Transmission | Hydrostatic |

| Speed range | 0-9.5 mph 0-15.3 km/h |

| Drive wheels | 20x10-8 Turf Master |

| Caster wheels | 11x4-5 |

| Warranty | 24 months |

| Engine | |

| Manufacturer/Model | FX691V |

| Power | Gorss at 3,600 rpm: 22 hp 16.4 kW |

| Displacement | 44.3 cu in. 726 cc |

| Cylinders | Two, V-twin |

| Crankcase capacity | With filter, 2.2 qt 2.1 L |

| Oil filter | Full flow, replaceable |

| Lubrication | Full pressure |

| Cooling | Forced air |

| Air cleaner | Heavy-duty canister type with safety element |

| Fuel system | |

| Fuel type | Gasoline |

| Fuel consumption | |

| Fuel tank capacity | 5.6 U.S. gal. 21.2 L |

| Fuel tank switch/shut-off valve | Yes |

| Electrical system | |

| Charge system | At 3,600 rpm, 20 amp |

| Battery voltage | 12 V |

| Cold cranking amp | |

| Hour meter | Digital |

| Operator presence starting system | Yes |

| Drivetrain | |

| Transmission | Hydrostatic |

| Hydraulic pumps | Hydro-Gear with fans, 0.73 cu in. 12 cc |

| Wheel motors | Hydro-Gear, 15 cu in. 246 cc |

| Travel speed | Speed range 0-9.5 mph 0-15.3 km/h Forward 0-9.5 mph 0-15.3 km/h Reverse 0-5.5 mph 0-8.9 km/h |

| Speed and direction control | Twin hand-controlled levers |

| Hydraulic capacity | With filter-wet, 2.9 qt 2.7 L Dry, 5 qt 4.7 L |

| Hydraulic oil cooler | |

| Filter | Spin-on replaceable |

| Buyer's note | |

| Warranty | 24 months |

| Tires | |

| Drive wheels | 20x10-8 Turf Master |

| Rear tires | |

| Load rating | 4 PR |

| Brakes | |

| Dynamic braking | Dual hand-controlled levers |

| Park brake | Tire engagement |

| Park brake actuation | Hand lever |

| PTO | |

| Type | Electro-Magnetic with brake, 200 lb-ft 271 Nm |

| Drive | Dual B-section V-belt with Kevlar® cord |

| Mower decks | |

| Size | 52 in. 132 cm |

| Deck construction | Fabricated steel, fixed mounting |

| Deck thickness | 7 gauge 0.18 in. 4.6 mm |

| Discharge | Side |

| Height-of-cut range | Increments 0.25 in. 0.64 cm 1.5-5 3.8-12.7 |

| Cutting width | 52 in. 132 cm |

| Blades | |

| Length | |

| Thickness | |

| Blade tip speed | 18,900 fpm 5,761 m/min |

| Number | Three |

| Wheels | |

| Caster wheel type | No-flat semi-pneumatic with sealed bearings |

| Caster wheels | 11x4-5 |

| Front anti-scalp rollers | Center, left |

| Rear anti-scalp rollers | |

| Dimensions | |

| Length | 66 in. 167.6 cm |

| Width | Deflector down, 66 in. 167.6 cm |

| Height | 47 in. 119 cm |

| Weight | 927 lb 420.5 kg |