2633VT VERTICAL TILLAGE

2633VT Vertical Tillage

- Gang angle 21° Front/19° Rear

- Working Widths from 20'9" to 40'8"

- Operating Speeds 7-10 mph

Features

Ground-engaging components on 2633VT

Ground-engaging components on 2633VT 2633VT pulled by 8370RT

2633VT pulled by 8370RTThe John Deere 2633VT offers six different sizes to fit any size operation, big or small.

| Model | 2633VT |

| Purpose | Vertical tillage |

| Working depth | Up to 75 mm (3 in.) |

| Standards | C-spring |

| Gang angle | 21 degrees front 19 degrees rear |

| Front gang blades |

|

| Rear gang blades | 560 mm x 5 mm (22 in. x 0.197 in.) solid shallow concavity 13 wave |

| Blade spacing | 185 mm (7.25 in.) |

| Gang bolt | 50 mm (2 in.) |

| Horsepower | 27-36 hp/m (8.5-11 hp/ft) working width |

| Working widths | 6.3 m to 12.4 m (20 ft, 9 in. to 40 ft, 8 in.) |

| Operating speed | 11-16 km/h (7-10 mph) |

Size | 6.3 m | 8 m | 8.9 m | 9.3 m | 10.2 m | 12.4 m |

Weight | 6796 kg | 9060 kg | 9230 kg | 9920 kg | 10025 kg | 12991 kg |

Number of blades | 68 | 88 | 96 | 104 | 112 | 136 |

Weight per blade | 100 kg | 103 kg | 96 kg | 95 kg | 90 kg | 95 kg |

Horsepower requirement | 131.2-170 kW | 164.8-213.3 kW | 184.2-237.9 kW | 196.1-254.3 kW | 208.8-270.7 kW | 259.5-335.6 kW |

Transport height | 3.05 m | 3.90 m | 4.30 m | 4.21 m | 4.62 m | 3.75 m |

Transport width | 4.11 m | 4.11 m | 4.11 m | 4.77 m | 4.77 m | 4.95 m |

John Deere's 2633VT comes equipped on 185-mm (7.25-in.) spacing with solid shallow concavity spherical blades on the front gang and solid shallow concavity wavy blades on the rear gang to size residue and mix soil.

A majority of the sizing is going to be done by the front gang, and the rear gang is going to do the mixing. John Deere designed its vertical tillage tool to chop stalks to an acceptable size and begin soil mixing for breakdown, yet leave a considerable amount of residue on the cover.

The 2633VT comes equipped with 185-mm (7.25-in.) spacing on the front and rear gang. Both blade sizes on front and rear gang are 560 mm x 5 mm (22 in. x 0.197 in.). Optional 560-mm x 6.5-mm (22-in. x 0.256-in.) blades are available on front gang only.

Front solid shallow concavity spherical blade

Solid shallow concavity spherical blade

Solid shallow concavity spherical blade- Chops and sizes residue

- Manages weeds

- Manages root balls

- Removes field ruts

Rear solid shallow concavity wavy blade

Solid shallow concavity wavy blade

Solid shallow concavity wavy blade- Mix soil and residue

- Aerates soil

- Anchors residue

Front and rear 185-mm (7.25-in.) spacing

185-mm (7.25-in.) blade spacing

185-mm (7.25-in.) blade spacing

- Ideal for seedbed preparation

- Maximizes chemical incorporation

| Blade type | Solid spherical blade | Solid wavy blade |

| Thickness |

| 5 mm (0.197 in.) |

| Concavity | Shallow | Shallow |

| Diameter | 560 mm (22 in.) | 560 mm (22 in.) |

| Recommended soil types | All soil types | All soil types |

51-mm (2-in.) gang bolts

51-mm (2-in.) gang bolts Gang tension system

Gang tension systemJohn Deere's 2633VT Vertical Tillage tool provides an innovative approach to tension gang bolts.

Hydraulic fore-aft leveling

Hydraulic fore-aft levelingHydraulic fore-aft leveling comes as standard equipment with John Deere's 2633VT Vertical Tillage tool. Operators can level the machine from the comfort of the tractor cab.

Residue management

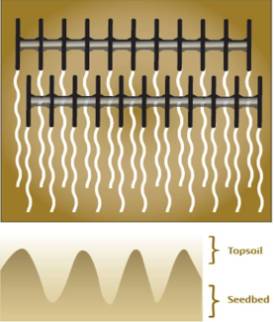

Residue managementWhether the plan is to use the 2633VT in the spring or fall, this machine was designed to handle any residue management situation. With a 21-degree angle on the front gang and 19-degree gang angle on the rear gang, this tool was created to have aggressive sizing and chopping ability in tough residue in the fall and to have finishing characteristics to build an ideal seedbed in the spring.

Shallow gang angle

Shallow gang angle Aggressive gang angle

Aggressive gang angleShallow gang angle vertical tillage tools can leave a wavy, washboard effect unsuitable for a proper seedbed. The 2633VT implement has an aggressive gang angle to help anchor residue, manage weeds and root balls, and create an even, smooth seedbed under the topsoil.

As crop yields increase, so does the amount of residue after harvest. The John Deere 2633VT allows producers to prepare soil for planting in the spring and residue management in the fall.

Utilize the residue calculator to identify the optimal residue management solution to meet the producer’s needs.

Hydraulic rolling basket with down pressure

Hydraulic rolling basket with down pressure Hydraulic rolling basket - in raised position

Hydraulic rolling basket - in raised positionThe 2633VT offers an active hydraulic rolling baskets that give the operator wide-ranging adjustability for a variety of conditions. The drawbars and rolling basket on the rear harrow are built with strength in mind for demanding vertical tillage conditions.

The system was designed to have the ability to run the rolling baskets in three different positions:

- Raised

- Allows the operator to raise the rolling baskets in harsh, muddy conditions

- Float

- Allows the operator to float the rolling baskets to lightly fluff soil

- Apply down pressure

- Allows the operator to adjust the basket pressure to provide consistent contact with the ground

- Provides a firm seedbed

- Shatters root balls

The hydraulic rolling basket is offered with a round bar, flat bar, or knife-edge. The flat bar is not recommended for rocky conditions. The knife-edge is best for heavier, wet soil.

Maintenance-free bearing in rolling basket

Maintenance-free bearing in rolling basket Maintenance-free bearing in rolling basket

Maintenance-free bearing in rolling basketWith these rolling baskets, a cast frame was designed to encase the bearing in a high-density polymer liner to allow dynamic movement and maintenance-free characteristics. Similar to the gangs on the 2633VT, the active hydraulic rolling baskets feature maintenance-free bearings to minimize non-productive activities.

Hydraulic rolling basket down pressure valve

Hydraulic rolling basket down pressure valve Hydraulic flat bar rolling basket harrow

Hydraulic flat bar rolling basket harrow Hydraulic knife-edge rolling basket harrow

Hydraulic knife-edge rolling basket harrowIn order to change the rolling basket down pressure, simply rotate the down pressure valve dial clockwise to increase pressure and counterclockwise to decrease pressure.

John Deere’s 2630 Series Disks and Vertical Tillage Implements feature extended-life bearings. These more durable and reliable bearings allow producers to customize bearing maintenance for specific growing conditions and soil types.

The flange-mounted bearing and sealing system features improved contamination resistance. The advanced seal material is highly resistant to wear and damage caused by abrasive soils and other crop materials. The design of these are more durable and reliable than previous bearings.

The design of this bearing system allows for dynamic self-alignment to the gang bolt, as opposed to trunnion-mounted bearings that have limited alignment capability. This system features additional freedom of movement, accommodating a wider variety of field conditions. The bearing system has been designed to decrease stress and fatigue on the inner rolling surfaces, supporting extended bearing life.

The bearing and seal design allows for a limited, seasonal maintenance interval to minimize downtime. They also allow producers to customize the maintenance for specific growing conditions and soil types. The multi-lipped sealing system cannot be damaged by frequent greasing. It allows bearings to accept grease within the bearing as well as provide grease to the outer bearing surface to eliminate wear between the bearing and housing. With this design, the bearings can accept grease even if misaligned to the housing.

The 2630 Series Disks offer multiple upgrades and new items as options versus the 2620 Series Disks to enhance the machine. Check out the following video sharing more about the new 2630 Series Disks.

Extended-life bearings

John Deere’s 2630 Series Disks and Vertical Tillage Implements feature extended-life bearings. These more durable and reliable bearings allow producers to customize bearing maintenance for specific growing conditions and soil type.

TruSet™ side-to-side feature

John Deere TruSet system is featured in base equipment for the 2630 Series Disks and Vertical Tillage Implements. TruSet side-to-side is also available and features individual section leveling.

Knife-edge hydraulic rolling basket

The hydraulic rolling basket is now offered with a round bar, flat bar, or knife-edge. The knife-edge is best for heavier, wet soil, and can be used in rocky conditions.

Radial tires

The 2630 Series Disks and Vertical Tillage Implements feature radial tires for the mainframes in base equipment. Radial tires are available as an option on the wing frame and stabilizer wheels. These tires are designed to offer longer wear life and help minimize compaction with a wider plate and lower inflation pressures.

Stabilizer wheels

Producers can choose either mechanical stabilizer wheels or TruSet hydraulic stabilizer wheels as an option. Stabilizer wheels help to maintain a consistent, level depth and are recommended for operation on rolling ground. The mechanical stabilizer wheels can be manually adjusted with a turnbuckle. TruSet with side-to-side leveling capabilities also enables operators to control the TruSet hydraulic stabilizer wheels from the cab while on the go.