N500C CENTRAL COMMODITY SYSTEM CCS

Central Commodity System (CCS™)

- Electric drive with Section Control

- Wide variety of working widths and row spacings

- Latest John Deere technologies

- Easier access to meters

Features

N500C with SeedMetering2

N500C with SeedMetering2 N500C in the field

N500C in the fieldThe N500C is designed for no-till seeding. The N500C with SeedMetering2 offers accurate volumetric metering in a compact tank-mounted-on-frame design, with the convenience of the Central Commodity System (CCS™) bulk-fill capabilities.

The N500C is available in single- or dual-rank designs, with 9.15-m, 11-m, 12.2-m, and 12.8-m (30-ft, 36-ft, 40-ft, and 42-ft) working widths. The single-rank N500C is available in 38.1-cm (15-in.) row spacing, making for a highly productive soybean seeding machine, while the dual-rank models are available in 19-cm or 25.4-cm (7.5-in. or 10-in.) row spacings. The dual-rank models also feature an optional dual row spacing package, which allows them to seed in their standard spacing or lock-up one rank and seed in 38.1-cm or 50.8-cm (15-in. or 20-in.) row spacings.

The productivity of the CCS comes standard with the N500C. The CCS bulk-fill tanks feature 3523.9-L (100-bu) capacity on the 9.15-m (30-ft) to 11-m (36-ft) models. The 12.2-m (40-ft) and 12.8-m (42-ft) models offer 4228.7 L (120 bu) of capacity to allow operators to seed more acres before stopping to refill.

The N500C features the Pro-Series™ No-Till Openers. With well over one million no-till openers in the field today, this proven opener offers accurate seed placement with the exclusive active hydraulic downforce ground-following system while minimizing moisture loss with its low-disturbance opener design.

The tank on the N500C has been moved up and back to allow for better access to the meters. The blower fan has been relocated to the front of the tank to allow non-obstructed access to all four meters.

Rear of N500C machine

Rear of N500C machine Relocated blower fan

Relocated blower fan Easy meter access

Easy meter accessThe updated tank design is also larger. The 9.15-m (30-ft) to 11-m (36-ft) models offer a 3523.9 -L (100-bu) tank. The 12.2-m (40-ft) and 12.8-m (42-ft) models offer a 4228.7-L (120-bu) tank.

3523.9-L (100-bu) tank

3523.9-L (100-bu) tankTank cleanout has also been improved. Producers can place a seed box or conveyer under the tanks to empty out excess seed. The tank has been designed so there is minimal seed left in the tank after it has been emptied.

Cleanout with a seed box

Cleanout with a seed box Cleanout with seed tender

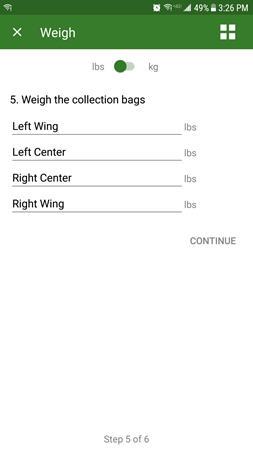

Cleanout with seed tenderCalibrating the meters has also been improved thanks to electric drive metering. The N500C is calibrated stationary similar to larger air carts. Catch bags are placed under each meter, and the meters turn a pre-determined amount of revolutions. Catch bags are weighted and entered into the SeedPlus app or on the Gen 4 display in order to generate a meter displacement value (MDV).

Calibrating the meters

Calibrating the metersThe N500C offers 33x15.5R16.5 tires standard on all machines, resulting in better floatation and less compaction and allowing operators to get into the field sooner and stay in the field longer. The mainframe is also equipped with walking beams to allow for better ground following.

500/40R16.5 tires with walking beam

500/40R16.5 tires with walking beam 33x15.5R16.5 tires with walking beam

33x15.5R16.5 tires with walking beam 31x13.5R15 tires on wing frame

31x13.5R15 tires on wing frame| Option code | Width | Mainframe front tire size | Number of tires | Mainframe rear tire size | Number of tires | Wing frame tire size | Number of tires |

| 3610 | All | 33x15.5R16.5 | 4 | 33x15.5R16.5 | 4 | 31x13.5R15 | 4 |

| 3611 | All | 33x15.5R16.5 | 4 | 33x15.5R16.5 | 4 | 31x13.5R15 | 8 |

| 3612 | 9.5/11-m (30/36-ft) | 33x15.5R16.5 | 4 | 500/40R16.5 | 4 | 33x15.5R16.5 | 8 |

| 3613 | 12.2/12.8-m (40/42-ft) | 500/40R16.5 | 4 | 500/40R16.5 | 4 | 33x15.5R16.5 | 8 |

Tire area comparison

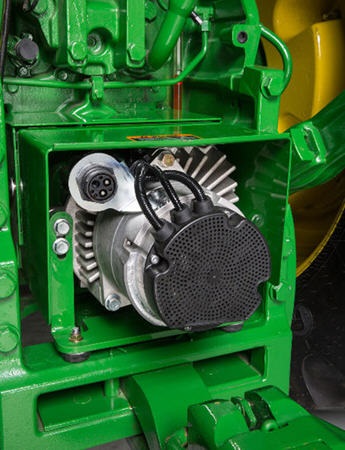

Tire area comparisonFor the first time, meter sections are controlled with electric motors. Each meter section has its own electric drive motor. This eliminates the need for a variable-rate drive hydraulic motor or a ground drive wheel. This also enables the SectionCommand system and variable/prescription seeding.

Electric drive motor on meter

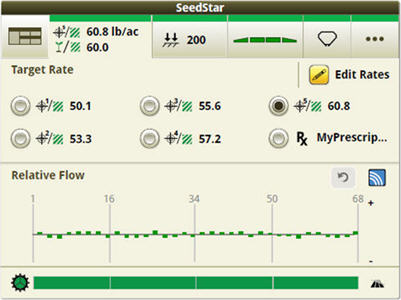

Electric drive motor on meter SeedStar run page showing four sections and prescription (Rx) seeding

SeedStar run page showing four sections and prescription (Rx) seedingPerscription/variable-rate seeding allows growers to apply the right amount of seed depending on predetermined management zones. Four-section SectionCommand has shown a potential seed savings of 4 to 6 percent depending on field size and shape.

Power generation

The electric motors are powered by a power take-off (PTO) power generation unit or an onboard hydraulic power generator. Growers can choose either of these options based on their tractor limitations. The on-board system utilizes power beyond, whereas the PTO system frees up hydraulic capacity on the tractor as the PTO powers the generator.

PTO power generation unit

PTO power generation unit On-board power generation unit

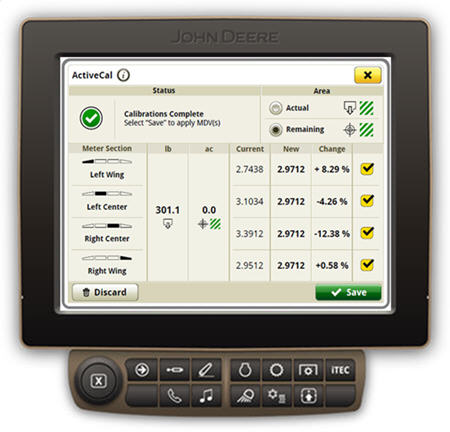

On-board power generation unit ActiveCal initiated on a C850

ActiveCal initiated on a C850 ActiveCal initiated on an N500C

ActiveCal initiated on an N500CThe more frequently calibration is completed, the more accurate a seeder will be. A number of variables, including product weight and changing climate conditions throughout the day, will have an effect on any volumetric metering system; with the John Deere ActiveCal system, calibration can be done from the cab of the tractor, while seeding, to minimize the variation in product metering.

The process to calibrate the implement starts with the Gen 4 4600 CommandCenter™ Display in the work setup page, where the operator defines product types, rates and selects meter rollers. Based on information entered into the work setup page, a preconfigured meter displacement value (MDV) will populate per meter. An initial manual calibration will give the most accurate MDV to start with. However, the preconfigured MDV will be a good starting point for growers who do not wish to manually calibrate.

The operator engages ActiveCal while stationary by selecting the button on the screen and then begins seeding. When enough product has been metered out, typically after about 8-12 acres, the Gen 4 CommandCenter will prompt the operator to stop when convenient to do so. At that time, the data points are calculated and a new MDV with percent difference is displayed on screen. The operator can accept or reject the new MDV. If accepted, the system automatically calibrates to the new MDV. If rejected, the system continues at the previously calibrated numbers.

Tank scales provide tank weights to ActiveCal system

Tank scales provide tank weights to ActiveCal system RelativeFlow blockage sensing

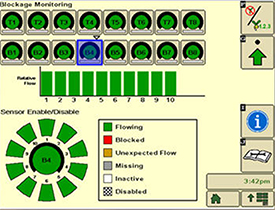

RelativeFlow blockage sensingWith the RelativeFlow blockage system, operators can see the flow rate of both seed and fertilizer from inside the tractor cab. Sensors on delivery hoses monitor the relative rate of product flow. An easy-to-read display clearly visualizes relative product flow across the drill, from opener to opener. This exclusive technology gives a better view of what is happening across the tool in order to spot problems before blockage occurs.

RelativeFlow Blockage is available on the following models:

- 1890 - 15.2-m (50-ft) and 18.3-m (60-ft)

- P540 - 12.2-m (40-ft)

- P556 - 17.1-m (56-ft)

- P576 - 23.2-m (76-ft)

- N560F - 18.3-m (60-ft)

- N500C - all widths

- N530F - 9.1-m (30-ft)

- N540F - 12.2-m (40-ft)

- N543F - 13.1-m (43-ft)

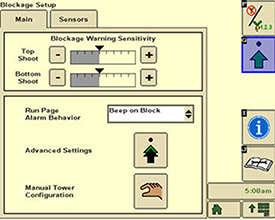

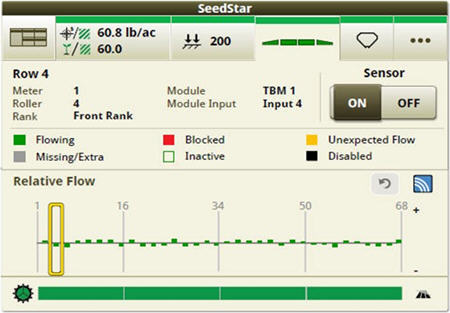

Below are the GreenStar™ 3 2630 Display screens for the blockage monitoring system. For complete details and information, see the owner’s manual.

Blockage monitoring screen

Blockage monitoring screenThe RelativeFlow system chart shows the amount of flow through each sensor on the selected tower. Sensitivity for the blockage system can be adjusted if desired, as shown below.

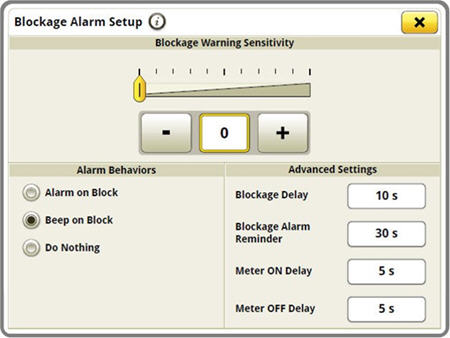

Blockage set-up screen

Blockage set-up screenBlockage warning sensitivity allows the producer to set and change the sensitivity of the sensors to meet their preferences. Increasing the sensitivity means the system is more likely to show a false blockage, while less sensitivity means the system is more likely to miss a blockage.

Multiple run-page alarm behavior options are available for selection.

Blockage set-up screen

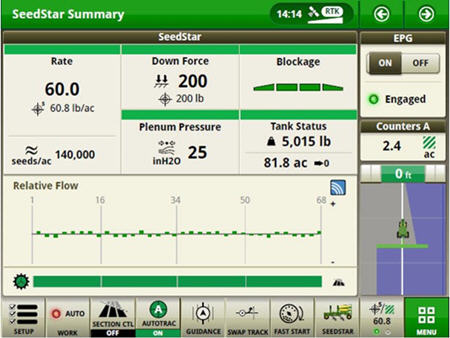

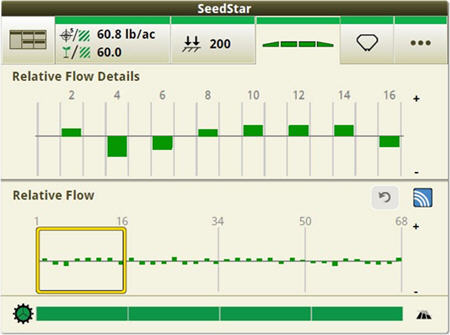

Blockage set-up screenBelow are the Gen 4 display screens for the blockage monitoring system on the N500C.

For complete details and information reference, the owner’s manual.

RelativeFlow Blockage configured run page

RelativeFlow Blockage configured run pageThe SeedStar™ system run page displays the five major run settings. Clicking on any of the tiles will take an operator to that specific page (shown below).

Operators can zoom into flow details by meter section when selecting Blockage tiles

Operators can zoom into flow details by meter section when selecting Blockage tiles Operators can zoom into the row level to access row/sensor information and turn a sensor on/off independently

Operators can zoom into the row level to access row/sensor information and turn a sensor on/off independently Blockage sensitivities and alarm delays are all set up on one easy-to-navigate screen

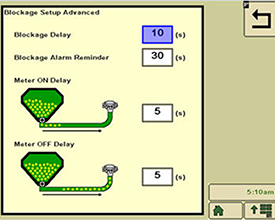

Blockage sensitivities and alarm delays are all set up on one easy-to-navigate screenBlockage alarm delays can be set up by clicking on the advanced settings button from the blockage set-up screen.

- A blockage delay is how long a blockage should occur before an alarm is sounded.

- The blockage alarm reminder is how often the alarm should sound when a blockage occurs.

- The meter on delay is the time from when the meter is turned on until the blockage sensor should start monitoring for blockage.

- The meter off delay is the time from when the meter is turned off until the blockage sensor should start monitoring to verify no flow.

For more detailed information, see the owner’s manual.

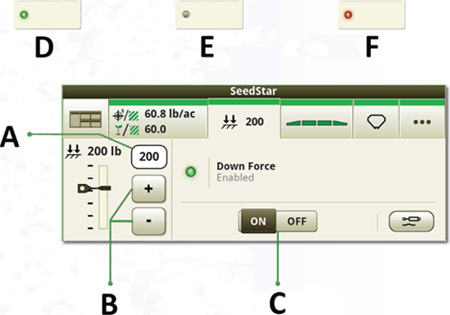

Downforce control from the Gen 4 display

Downforce control from the Gen 4 displayTruSet downforce allows operators to set downforce pressures from inside the cab. Downforce can easily be changed by the push of a button as soil conditions very. Proper downforce is directly related to a consistent seeding depth, which leads to improved even emergence, plant density, and maturity.

TruSet system quick-reference guide

TruSet downforce settings:

A. Select to manually input a value

B. Select to increase or decrease the target force of the openers

C. Downforce toggle button: select to enable or disable the downforce

D. Indicates that the downforce is enabled

E. Indicates that the downforce is disabled

F. Indicates that the downforce is enabled but not applying

SeedPlus app homescreen

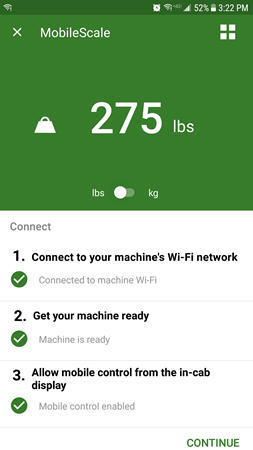

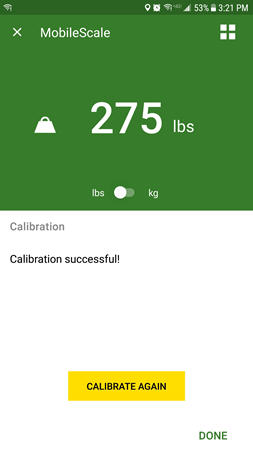

SeedPlus app homescreenTank scale weights and meter calibrations can be completed from an Android™ or iOS® mobile device anywhere around the machine.

Calibrating tank scales

Calibrating tank scales Calibration complete

Calibration completeTank scale weights can be viewed anywhere within 15.2 m (50 ft). The SeedPlus app can also be used to calibrate the tank scales as needed.

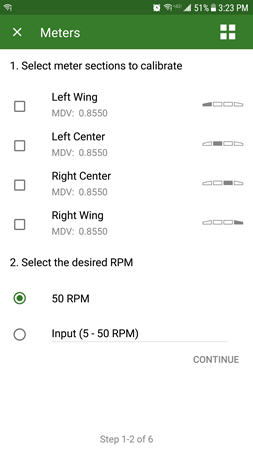

Initial meter calibration

Select meters to calibrate

Select meters to calibrateSelect the meters that toned to be calibrated. Calibrations are recommended every morning or when crops/seed sizes are changed.

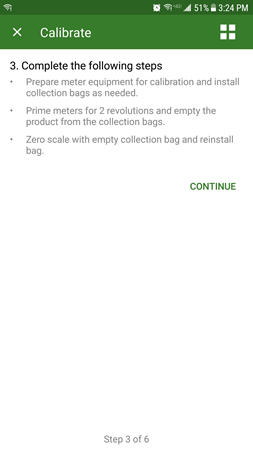

Steps to complete calibration

Steps to complete calibrationFollow the on-screen prompts to complete the calibration.

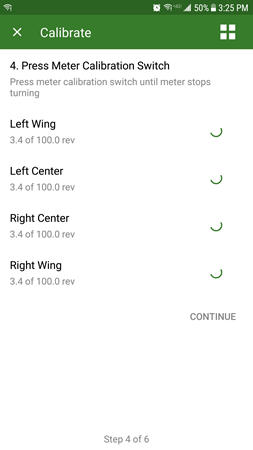

Press meter calibration switch

Press meter calibration switchOnce the catch bags are in place, hold down the meter calibration switch until the number of revolutions is complete.

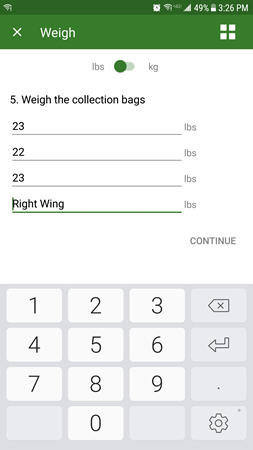

Weights of bag for each meter

Weights of bag for each meter Entering the weight of the bags

Entering the weight of the bagsEnter the weights of the bags into the app.

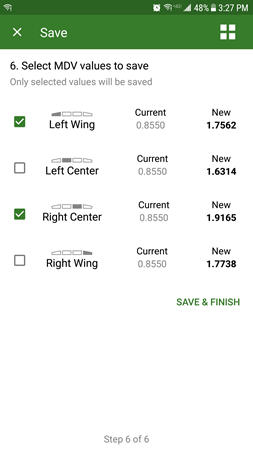

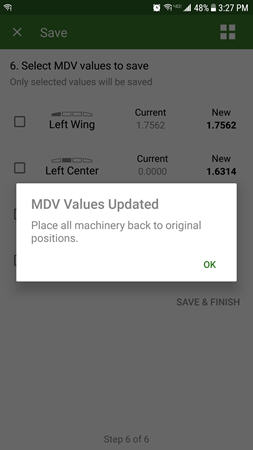

Save meter displacement values (MDV)

Save meter displacement values (MDV) MDV values are updated

MDV values are updatedThe SeedPlus app will calculate MDV based on the number of revolutions and the product weights. Operators can choose to accept the proposed MDV values or not.

Android is a trademark of Google LLC. iOS is a trademark of Cisco Technology, Inc. used under license by Apple Inc.

This document lists all the compatible equipment approved with the software update 19-2 release, and is subject to change with newer software updates. To ensure complete and proper compatibility, the most current version of implement control unit software, Generation 4 Display software, or compatible farm management information software (FMIS) should be used. Non-current software versions will require an update before support can be provided. Unapproved software version configurations will not be supported.

The software update 19-2 release is only compatible with 4600 CommandCenter™ v2 processors. Software update 17-2 is the last release that was compatible with 4600 v1 processors.

Server serial numbers are as follows:

- v1 = RWG prefix

- v2 = PCG prefix

Machine compatibility

John Deere Large Ag Tractors

| John Deere Large Ag Tractors (list of all automatically detected machines) | Model year | CommandCenter display | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | ||

| 9R/9RT/9RX Series | 2018 and newer | X | --- | X | X |

| 9R/9RT/9RX Series | 2015-2017 | * | --- | X | X |

| 9R/9RT Series | 2012-2014 | --- | --- | X | X |

| 9030/9030T Series | 2008 and newer | --- | --- | X | X |

| 9020/9020T Series | 2002-2007 | --- | --- | X | --- |

| 9000 Series | 1997-2001 | --- | --- | X | --- |

| 9000T Series | 2000-2001 | --- | --- | X | --- |

| 8R/8RT Series | 2018 and newer | X | --- | X | X |

| 8R/8RT Series | Mid-2014 - 2017 | * | --- | X | X |

| 8R/8RT Series | 2010-2013 | --- | --- | X | X |

| 8030/8030T Series | 2006 and newer | --- | --- | X | X |

| 8020/8020T Series | 2002-2005 | --- | --- | X | --- |

| 8010/8010T Series | 2000-2002 | --- | --- | X | --- |

| 8000 Series | 1994 | --- | --- | X | --- |

| 8000T Series | 1997-1999 | --- | --- | X | --- |

| 7R Series | 2018 and newer | X | X | X | X |

| 7R Series | 2014-2017 | * | --- | X | X |

| 7R Series | 2011-2013 | --- | --- | X | X |

| 7J Series | 2018 and newer | --- | --- | X | X |

| 7030 Series | 2007 and newer | --- | --- | X | X |

| 7030 Series (Large Frame) | 2007 and newer | --- | --- | X | X |

| 7030 Series (Small Frame) | 2006 and newer | --- | --- | X | X |

| 7010 Series | 1997-2003 | --- | --- | X | --- |

| 7000 Series | 1992-1996 | --- | --- | X | --- |

| 6030 Series (Small Frame) | 2006 and newer | --- | --- | X | X |

| 6000 Series | 1992-1998 | --- | --- | X | --- |

| 6010 Series | 1999-2002 | --- | --- | X | --- |

| 6R Series | 2018 and newer | X | X | X | X |

| 6R Series (Final Tier 4) | 2015-2017 | * | --- | X | X |

| 6R Series (Interim Tier 4) | 2013-2015 | --- | --- | X | X |

| 6M Series | 2013 and newer | --- | --- | X | X |

| 6J Series | 2018 and newer | --- | --- | X | X |

| 5R Series | 2019 and newer | --- | --- | X | X |

*NOTE: For latest Precision Ag functionality, update machines equipped from the factory with v1 processor to v2. The 4640 Universal Display is not compatible with SeedStar™ 4HP Planters when installed on 00, 10, and 20 Series Tractors.

John Deere Nutrient Applicators

John Deere Nutrient Applicators | Model year | CommandCenter | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | ||

| F4365 High-Capacity Nutrient Applicator | 2017 and newer | X | --- | --- | --- |

John Deere Self-Propelled Sprayers

| John Deere self- propelled sprayers | Model year | CommandCenter | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | ||

| 4 Series Sprayers | 2018 and newer | X | --- | --- | --- |

| 4 Series Sprayers | 2013 - 2017 | --- | --- | X | --- |

| 4940 | 2012 - 2014 | --- | --- | X | --- |

| 4630 | 2008 and newer | --- | --- | X | --- |

| 4730 | 2008 and newer | --- | --- | X | --- |

| 4830 | 2008 - 2014 | --- | --- | X | --- |

| 4930 | 2008 - 2013 (SN 4000+) | --- | --- | X | --- |

| R4040i | 2014 and newer | --- | --- | X | --- |

| R4050i | 2017 and newer | --- | --- | X | --- |

| 5430i | 2008 - 2014 | --- | --- | X | --- |

| Hagie™ sprayers | 2014 and newer | Compatible with GreenStar™ 3 2630 Displays and 4640 Universal Displays* | |||

*NOTE: When using the 4640 Universal Display on a Hagie Sprayer, additional mounting and harnessing may be required.

- 4640 Ram™ Mount - SJ34503

- 4640 power/video harness - BPF11527 (1-3 video plus machine power), PF90687 (machine power only)

NOTE: Current John Deere/Hagie field kits only offer GreenStar 3 2630 Display parts.

NOTE: AutoTrac™ Vision/AutoTrac RowSense and multi-rank section control are not supported on Hagie at this time.

NOTE: VIN detection is not supported on Hagie Sprayers at this time.

John Deere Self-Propelled Forage Harvesters (SPFH)

John Deere Self-Propelled | Model year | CommandCenter | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | ||

| 9000 Series SPFH | 2019 and newer | --- | --- | X | --- |

| 8000 Series SPFH | 2015 and newer | --- | --- | X | --- |

John Deere combines

| John Deere combines | Model year | CommandCenter | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | ||

| S700 Series | 2018 and newer | X | --- | --- | --- |

| S430 and S440 | 2017 and newer | X | --- | --- | --- |

| S600 Series | 2012 - 2017 | --- | --- | X | X |

| S540 and S550 Series | 2012 and newer | --- | --- | X | X |

| T-Series | 2012 and current | --- | --- | X | X |

| W-Series | 2012 and current | --- | --- | X | X |

| 70 Series | 2008 - 2013 | --- | --- | X | X |

NOTE: Competitive equipment may be compatible with 4640 Universal Display and 4240 Universal Display. For additional compatibility information, contact a John Deere dealer.

Equipment compatibility

John Deere planters

SeedStar™ 4HP planters are only compatible with 4600 CommandCenter displays with a version 2 (v2) processor and 4640 Universal Displays. Displays should be running Generation 4 OS software version 10.10.404-390 or newer and the most current version of tractor applications to be compatible with SeedStar 4HP planter applications. Additionally, dual-display mode is available for use with SeedStar 4HP planter applications, along with Generation 4 Extended Monitor. SeedStar 4HP planters are compatible with no more than two GreenStar Rate Controllers.

The SeedStar 2 configuration below is available only on factory-installed model year 2011 and newer planters and may be field-installed on model year 2009 and 2010 planters. Green PM/PA controllers (factory-installed on model year 2009 and 2010 planters) are not supported with a Generation 4 display.

A Service ADVISOR™ tool (available at a John Deere dealer) is needed to update SeedStar 2, SeedStar XP, and SeedStar 3 HP software. Documentation is not supported when using a rate controller to control row clutches on a John Deere planter.

| John Deere planters | Control unit name | Software version (or newer) | CommandCenter display | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240* | |||

| SeedStar 2 | Black PM1 | 22.0 | X | X | X | X |

| Black PA1, (if available PA 2) | 22.0 | X | X | X | X | |

| Green PM1 | 10.11 | --- | --- | --- | --- | |

| Green PA1 (if available PA 2) | 10.11 | --- | --- | --- | --- | |

| SeedStar XP | Black PM1 | 22.0 | X | X | X | X |

| Black PA1, (if available PA 2) | 22.0 | X | X | X | X | |

| PM2 | 7.0 | X | X | X | X | |

| SeedStar 3 HP | Planter Main A (PCMA) | 5.0 | X | X | X | X |

| Planter Main B (PCMB or MMC) | 8.0 | X | X | X | X | |

| Row-unit Controller (RUC) | 2.0 | X | X | X | X | |

| EPG | 3.0 | X | X | X | X | |

| SeedStar 4HP | Planter Apps | 10.4.2-29 | X | --- | X | --- |

| Planter Main A (PMCA) | 5.0 | X | --- | X | --- | |

| Planter Main B (PMCB or MMC) | 6.0 | X | --- | X | --- | |

| Row-unit Controller (RUC) | 3.0 | X | --- | X | --- | |

| Electrical Power Generation (EPG) | 5.0 | X | --- | X | --- | |

| Electrical Power Module, 2 (PC2) | 3.0 | X | --- | X | --- | |

*NOTE: For implements requiring ground speed input (radar), utilizing a 4240 Universal Display may require an additional 4240 Radar speed kit.

John Deere Air Seeders

The C850 Air Cart requires a 4600/4200 CommandCenter Display or a 4640/4240 Universal Display. GreenStar 3 2630 monitors are not supported. Additionally, C850 Air Carts and AutoTrac Implement Guidance (passive) are compatible with software update 18-2 and newer.

| John Deere Air Seeder | Model year/control unit name | Software version (or newer) | CommandCenter | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240* | |||

| C850 Air Cart | Cart Master Controller (CMC) | 12 | X | X | X | X |

| Mini Tank Controller (TXC) | 6 | X | X | X | X | |

| Front, Middle, Rear Tank Controller (TCU) | 6 | X | X | X | X | |

| 1870 Seeding Tool - TruSet™ system | 2017 and newer (IDC) | 5.0 | X | X | X | X |

| 1870 Seeding Tool - RelativeFlow™ blockage sensors | 2017 and newer (BMU) | 4.0 | X | X | X | X |

| 1910 Air Cart - ground drive | 2009 and newer | 3.0 | X | X | X | X |

| 1910 Air Cart - hydraulic drive | 2013 and newer | 8.00 | X | X | X | X |

| Seeding tools with air-run blockage - primary blockage | 2009 and newer (BMU) | 12.0 | X | X | X | X |

| Seeding tools with air-run blockage - air-run blockage | 2009 and newer (BMU) | 12.0 | X | X | X | X |

| Member Module | 5.0 | X | X | X | X | |

| 1990 Central Commodity System (CCS™) | 2009 and newer (BMU) | 12.0 | X | X | X | X |

| N500C Series | Seeding apps | 10.1.495-31 | X | --- | X | --- |

| SMCA or SMC | 2.0 | X | --- | X | --- | |

| SMCB or BMU | 2.0 | X | --- | X | --- | |

| EPG | 2.0 | X | --- | X | --- | |

*NOTE: For implements requiring ground speed input (radar), utilizing a 4240 Universal Display may require an additional 4240 Radar speed kit.

John Deere Tillage

| John Deere Tillage | Control unit name | Software version (or newer) | CommandCenter | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | |||

| AccuDepth™ cultivator | Implement Depth Control (IDC) | 11 | X | X | X | X |

| 2730 with TruSet | Tillage Controller 1 (TC1) | 2.66K | X | X | X | X |

| 2230 with TruSet | Tillage Controller 1 (TC1) | 2.75K | X | X | X | X |

| 2330 with TruSet | Tillage Controller 1 (TC1) | 3.35K | X | X | X | X |

| 2620/2630 with TruSet | Tillage Controller 1 (TC1) | 2.95K | X | X | X | X |

| 2720 with TruSet | Tillage Controller 1 (TC1) | 2.24K | X | X | X | X |

| 2660VT with TruSet | Tillage Controller 1 (TC1) | 2.03K | X | X | X | X |

| 2430 with TruSet | Tillage Controller 1 (TC1) | 2.14K | X | X | X | X |

| 2510H with TruSet | Tillage Controller 1 (TC1) | 2.85K | X | X | X | X |

*NOTE: For implements requiring ground speed input (radar), utilizing a 4240 Universal Display may require an additional 4240 Radar speed kit.

John Deere Round Balers

| John Deere Round Balers | Control unit name | Software version (or newer) | CommandCenter | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | |||

| 0 Series | Baler Automation | 10.07 | X | X | X | X |

| 9 Series Premium | Baler Automation | 7.16 | X | X | X | X |

| V451R/V461R | Baler Automation | 11.5 | X | X | X | X |

John Deere Large Square Balers

| John Deere Large Square Balers Including Harvest Tec applicator and PhiBer accumulator | Control unit name | Software version (or newer) | CommandCenter | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | |||

| 0 Series | Gen 4 VT | 3.04 | X | X | X | X |

| 1 Series | Gen 4 VT | 5.07 | X | X | X | X |

Precision Ag Technology software compatibility

| John Deere control units | Control unit name | Software version (or newer) | CommandCenter display | Universal Display | ||

| 4600 v2 | 4200 | 4640 | 4240 | |||

| *StarFire 6000 Receiver | --- | 4.10J | X | X | X | X |

| StarFire 3000 Receiver | --- | 2.32H | X | X | X | X |

| *Modular Telematics Gateways (MTG) - 3G | --- | 21.03 | X | X | X | X |

| *MTG - 4G | --- | 25.01.746 | X | X | X | X |

| GreenStar Rate Controller | --- | 3.70K | X | X | X | X |

| GreenStar Rate Controller Dry | --- | 2.11A | X | X | X | X |

| *John Deere Rate Controller 2000 | --- | 1.13A | X | X | X | X |

| *AutoTrac Universal 200 | --- | 2.30A | --- | --- | X | X |

| *AutoTrac Universal 300 | --- | 3.22O | --- | --- | X | X |

| AutoTrac Controller 250 | --- | 11933B | --- | --- | X | X |

| *AutoTrac Controller - Deere | --- | 1.11B | --- | --- | X | X |

| AutoTrac Controller - Raven | --- | 3.2.29 | --- | --- | X | X |

| AutoTrac Controller - Reichhardt® | --- | SW 1.3 | --- | --- | X | X |

| AutoTrac RowSense™ | RG3 | AKK15783F | X | --- | X | --- |

| AutoTrac Vision | VGC | 4.01L | X | --- | X | --- |

| AutoTrac Turn Automation | --- | 19-2 | X | --- | X | --- |

| AutoTrac Implement Guidance | --- | 19-2 | X | --- | X | --- |

| Active Implement Guidance (VT) | Application 1100 | 2.71 T | X | X* | X | X* |

| iGrade™ | Application 1100 | 2.71 T | X | X | X | X |

| Distance Trip | Application 1100 | 2.71 T | X* | X | X | X |

| Gen 4 Extended Monitor | X | --- | X | --- | ||

| Wireless Data Server | Wireless Data Server | 1.541.2 (Planting) | X | --- | X | --- |

| Mobile Data Transfer | MyTransfer™ app | 3.8.6 (iOS®) | X | X | X | X |

| Connect Mobile app | Connect Mobile app | 8.0.1 or newer | X | --- | X | --- |

| Connect Mobile server | Connect Mobile server | 2.3.87-1 | X | --- | --- | --- |

| Mobile Weather | Application 1120 | 1.51 V | X | X* | X | X* |

| Manure Constituent Sensing | Manure Controller | 19.06 | X | --- | X | --- |

*NOTE: See additional information below.

StarFire Receivers

StarFire Receivers can be updated in the following ways:

- Receiver USB port (available only for StarFire 6000 Receivers)

- Generation 4 display USB port

- Remote software updates application (in ISOBUS VT app)

Additionally, StarFire iTC Receivers are no longer supported with software update 2017-1 and newer software. StarFire 6000 Receivers require software version 3.80F or higher when used with AutoTrac Implement Guidance.

John Deere Operations Center

To use RDA on a Generation 4 CommandCenter Display with a GreenStar 3 2630 Display connected in the same machine, GreenStar 3 2630 software version 3.22.1095 (SU2014-1) or higher is required (for 4600 CommandCenter Display and 4640 Universal Display only).

GreenStar Rate Controller and GreenStar Rate Controller Dry

GreenStar Rate Controller Dry is supported with display software update 2017-2 and newer. The 4600 and 4200 CommandCenter Displays and 4640 and 4240 Universal Displays support documentation and section control of up to five GreenStar Rate Controller units.

To update the GreenStar Rate Controller and GreenStar Rate Controller Dry, utilize a Generation 4 Display USB port. John Deere dealers can also utilize Service ADVISOR™. GDC 2.11A was the last software version available through Software Manager. GDC 2.20A has been available since spring 2015 and contains diagnostic language updates. This software can only be obtained through Service ADVISOR.

John Deere Rate Controller 2000

The Generation 4 Displays and John Deere Rate Controller 2000 can support documentation and control up to five operations. ISO controllers such as SeedStar or TruSet can be used alongside a John Deere Rate Controller 2000 that is documenting additional operations. The John Deere Rate Controller 2000 will not control the planter clutches or half-, third-, or quarter-width disconnects on a John Deere planter.

AutoTrac™ Vision

AutoTrac Vision Guidance Camera 19-1 software 4.01L is only compatible with RowGuidance 3 Controller software AKK15783F and GreenStar 3 2630 17-1 software 3.34.1345 or newer and Generation 4 18-1 software 10.10.404-345 or newer.

AutoTrac Universal 200, AutoTrac Universal 300, and AutoTrac Controller

AutoTrac Universal 200, AutoTrac Universal 300, and AutoTrac Controllers are for use with the 4640 Universal Display and 4240 Universal Display. Please see a John Deere dealer for exact model compatibility.

ISOBUS implements

Generation 4 Displays are compatible with one Agricultural Industry Electronics Foundation (AEF) certified ISOBUS implement; AEF-certified ISOBUS implements with Task Controller Section Control (TC-SC) functionality and AEF certification for TC-SC include sprayers, fertilizer spreaders, planters, seeders, manure applicators, etc. For third-party FMIS compatibility, reference the John Deere Operations Center.

A software update performed by an authorized ISOBUS implement dealer may be required to obtain compatible software. ISOBUS implements must be certified through the Agricultural Industry Electronics Foundation (AEF) to be recognized by the Generation 4 CommandCenter display. Visit www.aef-online.org for more information; visit www.aef-isobus-database.org for an active list of compatible implements.

ISOBUS implements with VT4 are now supported by Generation 4 Displays. Generation 4 Displays still support older VT versions (example: VT2 and VT3). If an implement is not loading after updating to Generation 4 software update 2017-2 (or newer on 4600 CommandCenter v2 processors), it is recommended that the implement manufacturer be contacted to get a software version that is either VT3 or VT4.

Extended monitor

When using an extended monitor with equipment visualized in ISOBUS VT Viewer and applying VT run page modules to two run pages shown at the same time, the extended monitor’s VT modules will not update. To mitigate this, only view VT modules on one run page at a time.

Implements without controllers

Implements without controllers can be documented as a stand-alone operation or with a rate controller from John Deere. Additionally, multiple implements without controllers cannot be documented together.

AutoTrac Implement Guidance (passive)

AutoTrac Implement Guidance is compatible with SeedStar 3HP, SeedStar 2 and SeedStar XP.

AutoTrac Implement Guidance is compatible with C850 Tow-Behind Air Carts with software update 18-2.

AutoTrac Implement Guidance is not compatible with the SeedStar 4 HP planters.

AutoTrac Implement Guidance is not compatible on 4240 Universal Displays for shared signal applications.

AutoTrac Turn Automation

To use the AutoTrac Turn Automation application, specific compatibility is required. AutoTrac Turn Automation is compatible with the following machines:

- 8030 Series Tractors

- 9030 Series Tractors (if equipped with PowerShift™ transmission)

- Model year 2012 and newer 6R Tractors (if equipped with Infinitely Variable Transmission [IVT™] and ITEC™ functionality)

- Model year 2011 and newer 7R Tractors (if equipped with CommandQuad™ transmission, e23™ PowerShift transmission, or IVT)

- Model year 2010 and newer 8R/RT Tractors

- Model year 2012 and newer 9R/RT/RX Tractors

NOTE: Integrated tractor IMS must be turned off on 30-Series Tractors to use AutoTrac Turn Automation on the Generation 4. Integrated Tractor iTEC must be turned off on the following tractors to use AutoTrac Turn Automation on the Generation 4:

- Model year 2012-2014 6R

- Model year 2011-2013 7R

- Model year 2010-2013 8R

- Model year 2012-2014 9R

NOTE: If instead an operator chooses to use the machine’s integrated IMS/iTEC functionality, then AutoTrac Turn Automation and iTEC must be turned off in the Generation 4 Universal Display.

AutoTrac Turn Automation is compatible with SeedStar 3HP, SeedStar 2 and SeedStar XP.

AutoTrac Turn Automation is NOT compatible with SeedStar 4HP planters.

Distance Trip documentation

A UCC2 Application Controller 1100 with 19-2 software running on a 4600 CommandCenter v2 server enables documentation of field operations. If a UCC2 replaces a UCC1 Application Controller 1100 on a CommandCenter v1 server, documentation is not available. Refer to Tech Manual Bulletin 137919 to determine server type.

Camera compatibility

Voyager® cameras are supported on Generation 4 Displays. All other camera types are not supported.

Non-John Deere Precision Ag

4600 CommandCenter v2 and the 4640 Universal Display are compatible with the following RS-232 configurations with software update 18-2 and newer:

- GPS receivers with serial port connection

- Will not enable AutoTrac guidance functionality

- Raven RS-232 control units (440, 450, or 660) on tractors configured as implement-based applications

- Generation 4 displays are not compatible with the DN345 Drawn Dry Spreader at this time.

Machine Communication Radio (MCR)

Generation 4 displays are not compatible with MCR.

APEX™ software

- Generation 4 display work data is not compatible with and cannot be viewed in APEX software.

- USB files including pre-assigned APEX tasks and iTEC™ Pro sequences will not import into Generation 4 displays.

NOTE: Gen 4 data is only compatible with the John Deere Operations Center. All Gen 4 activations are machine specific and cannot be transferred to a different machine. If not using WDT, an 8- to 32-GB USB is required to transfer data to and from the Gen 4 Display. Implement settings are display specific and cannot be imported or exported from the Gen 4 Display.

RAM is a trademark of National Products Inc. Hagie is a trademark of Hagie Manufacturing Company, LLC and similar to John Deere branded equipment, John Deere will support Hagie equipment. Reichhardt is a trademark of Reichhardt GmbH Steuerungstechnik. iOS is a trademark of Cisco Technology, Inc. used under license by Apple Inc. Android is a trademark of Google LLC. Voyager is a trademark of ASA Electronics, LLC.

Specifications

| Key Specs | n500c-central-commodity-system-ccs Current Model |

|---|---|

| Working widths | N530C - 9.15 m (30 ft) N536C - 11 m (36 ft) N540C - 12.2 m (40 ft) N542C - 13 m (42 ft) |

| Spacing | Dual rank: 7.5-in. (19.1 cm) spacing; 10-in. (25.4 cm) spacing Single rank: 15-in. (38.1 cm) spacing |

| Number of ranks | Single; Dual |

| Openers | Diameter 45.7 cm 18 in. Down pressure Up to 400 lbs. 19.1 cm (7.5-in.) models: 74.8-181.4 kg/opener (165-400 lb) 25.4 cm (10-in.) models: 74.8-181.4 kg/opener (165-400 lb) 38.1 cm (15-in.) models: 74.8-181.4 kg/opener (165-400 lb) Dual rank - 7.5-in. (19.1 cm) spacing: 48, 58, 64, 68 Dual rank - 10-in. (25.4 cm) spacing: 36, 44, 48, 50 Single rank - 15-in. (38.1 cm) spacing: 24, 28, 32, 34 |

| Sizes | |

| Working widths | N530C - 9.15 m (30 ft) N536C - 11 m (36 ft) N540C - 12.2 m (40 ft) N542C - 13 m (42 ft) |

| Spacing | Dual rank: 7.5-in. (19.1 cm) spacing; 10-in. (25.4 cm) spacing Single rank: 15-in. (38.1 cm) spacing |

| Number of ranks | Single; Dual |

| Number of sections | Dual rank - 7.5-in. (19.1 cm) spacing: 48, 58, 64, 68 Dual rank - 10-in. (25.4 cm) spacing: 36, 44, 48, 50 Single rank - 15-in. (38.1 cm) spacing: 24, 28, 32, 34 |

| Dimensions | |

| Transport height | N530C - < 3.68 m (12.08 ft) N536C - < 4.60 m (15.08 ft) N540C - < 4.50 m (14.75 ft) N542C - < 4.88 m (16 ft) |

| Transport width | N530C and N536C - < 4.42 m (14.5 ft) N540C and N542C - < 5.64 m (18.5 ft) |

| Road clearance | > 17.8 cm > 7.0 in. |

| Overall length | ≤ 9.1 m ≤ 29.9 ft |

| Centerframe width | N530C and N536C - 3.5 m (11.4 ft) N540C and N542C - 4.6 m (15.2 ft) Centerline of mainframe wheel support tube to centerline of wing wheel support tubes - N530C and N536C - 2.4 m (7.85 ft) N540C and N542C - 3.2 m (10.4 ft) |

| Weight before ballast | Dual rank - 7.5-in. (19.1 cm) spacing: N530C - ≤ 23,000 lb. (10,400 kg); N536C - ≤ 27,200 lb. (12,300 kg); N540C - ≤ 29,800 lb. (13,500 kg); N542C - ≤ 31,000 lb. (14,100 kg) Dual rank - 10-in. (25.4 cm) spacing: N530C - ≤ 20,400 lb. (9300 kg); N536C - ≤ 24,300 lb. (11,000 kg); N540C - ≤ 26,400 lb. (12,000 kg); N542C - ≤ 27,300 lb. (12,400 kg) Single rank - 15-in. (38.1 cm) spacing: N530C - ≤ 14,700 lb. (6700 kg); N536C - ≤ 16,900 lb. (7700 kg); N540C - ≤ 18,500 lb. (8400 kg); N542C - ≤ 19,200 lb. (8700 kg) |

| Available ballast | |

| Frame | Cross members 102x152 mm 4x6 in. End tubes 51x152 mm 2x6 in. Hitch 254x152 mm 10x6 in. |

| Clearance from rank to rank | 134 cm 52.8 in. Lateral frame clearance, opener to opener - 15 in. (38.1 mm) for 7.5-in (19.1 cm) models 20 in. (50.8 mm) for 10-in (25.4 cm) models |

| From ground to top of lid | N530C and N536C - ≤ 320 cm (126 in.) N540C and N542C - ≤ 310 cm (122 in.) |

| From ground to platform | ≤ 220 cm 85 in. |

| From ground to top of safety rail | ≤ 322.6 cm 127 in. |

| From ground to top of lights | N530C and N536C - ≤ 320 cm (126 in.) N540C and N542C - ≤ 310 cm (122 in.) |

| Centerline of mainframe wheel support tube to centerline of wing wheel support tubes | |

| Lateral frame clearance, opener to opener | |

| Tires | |

| Mainframe standard | (4) 33x15.5-16 on front, (4) 33x15.5-16 on rear |

| Mainframe bolt pattern | 8 bolts |

| Wings standard | (4) 31x13.5-15 NHS |

| Wings bolt pattern | 8 bolts |

| Centerframe tires and wheels | N530C and N536C - (4) 33x15.5-16 on front, (4) 500/40R16 on rear N540C and N542C - (4) 500/40R16 on front, (4) 500/40R16 on rear |

| Wing tires and wheels | (8) 33x15.5-16 |

| Wheel spacing, center frame | Width of duals, center to center N530C and N536C - 258.1 cm (101.6 in.) N540C and N542C - 322.1 cm (126.8 in.) Width outside to outside of dual pair, front - largest tire option 130.8 cm 51.5 in. Width outside to outside of dual pair, rear 130.8 cm 51.5 in. Tire width, front - largest tire option N530C and N536C - 40.6 cm (16 in.) N540C and N542C - 50.8 cm (20 in.) Tire width, rear - largest tire option 50.8 cm 20 in. |

| Openers | |

| Style | |

| Rank lock-up | |

| Disk | Diameter 45.7 cm 18 in. Angle 7-degree angle 45.7 cm (18-in.) disk blade at 7-degree angle |

| Down pressure | Up to 400 lbs. 19.1 cm (7.5-in.) models: 74.8-181.4 kg/opener (165-400 lb) 25.4 cm (10-in.) models: 74.8-181.4 kg/opener (165-400 lb) 38.1 cm (15-in.) models: 74.8-181.4 kg/opener (165-400 lb) |

| Depth control | Gauge wheel size 4.5 in. x 16 in. or 3 in. x 16 in. Gauge wheels - 11.4x40.6 cm (4.5x16 in.) Gauge wheel adjustment - 1.3-8.9 cm (0.5-3.5 in.) in 0.64 cm (0.25 in.) increments |

| In-Furrow press wheel | Material Rubber Packing force Adjustable down-pressure from 2.3 to 20.4 kg 5 to 45 lb 2.54x25.4 cm 1x10 in. |

| Furrow closing | Description Cast wheel at 15-degree vertical angle Serrated closing wheel at 15-degree vertical angle Size Cast wheel: 2.54x30.5 cm 1x12 in. Serrated closing wheel: 302 mm 11.9 in. Material Cast Down force Down-pressure from 11.8-19.5 kg 26-43 lb Serrated or smooth cast closing wheel |

| Double-Shoot capable | |

| Seed Metering | |

| Description | Central volumetric metering |

| Crops | Barley, oats, rice, sorghum, soybean, wheat |

| Max Volumetric Seeding Rates - Barley | ≤ 1,000,000 seeds per acre (2,470,000 seeds per hectare) |

| Max Volumetric Seeding Rates - Oats | ≤ 2,500,000 seeds per acre (6,180,000 seeds per hectare) |

| Max Volumetric Seeding Rates - Rice | ≤ 1,700,000 seeds per acre (4,200,000 seeds per hectare) |

| Max Volumetric Seeding Rates - Milo/Sorghum | ≤ 100,000 seeds per acre (247,000 seeds per hectare) |

| Max Volumetric Seeding Rates - Soybean | ≤ 250,000 seeds per acre (618,000 seeds per hectare) |

| Max Volumetric Seeding Rates - Wheat | ≤ 2,970,000 seeds per acre (7,300,000 seeds per hectare) |

| Metering Drive Type | Electric |

| Seed Storage | |

| Tank Description | Central, non-pressurized polyethylene tank |

| Total Tank Capacity | N530C and N536C - 3500 L (100 bu) N540C and N542C - 4200 L (120 bu) |

| Tank Fill Screen | Optional; one per tank opening |

| Tank Scales | Optional; provides summed commodity weight |

| Seed Distribution | |

| Type | Pneumatic |

| Blower | 45 cm (17.7 in.) diameter impeller |

| Blower drive type | Hydraulic |

| Distribution hose size | 1 in. (2.54 cm) ID for 38.1 cm (15 in.) row spacing 1.13 in. (3.13 cm) ID primaries with 1 in. (2.54 cm) ID secondaries for 19.1 and 25.4 cm (7.5 and 10 in.) row spacings |

| Equipment compatibility (at 1.5 in. seeding depth and 8 mph) | |

| Tractor drawbar power required, 7.5-in (19.1 cm) models | N530C - ≥ 219 kW (293 hp) N536C - ≥ 254 kW (341 hp) N540C - ≥ 278 kW (373 hp) N542C - ≥ 292 kW (392 hp) |

| Tractor drawbar power required, 10-in (25.4 cm) models | N530C - ≥ 179 kW (240 hp) N536C - ≥ 207 kW (278 hp) N540C - ≥ 225 kW (301 hp) N542C - ≥ 232 kW (311 hp) |

| Tractor drawbar power required, 15-in (38.1 cm) models | N530C - ≥ 137 kW (183 hp) N536C - ≥ 154 kW (206 hp) N540C - ≥ 166 kW (222 hp) N542C - ≥ 172 kW (231 hp) |

| Tractor requirements | |

| Minimum number of SCV's | Three - one fold, one opener raise/lower, and one seed distribution blower |

| Hydraulic Power Beyond | Required for in-cab opener downforce and electric power generation |

| Minimum hydraulic capacity | 58 gpm (220 L/min) at 2900 psi (200 bar) |

| Minimum electrical capacity | 48 A at 12 VDC |